|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Imagemaker Arts & Collectibles

Bronze Foundry

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

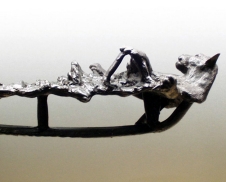

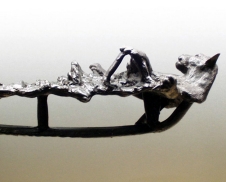

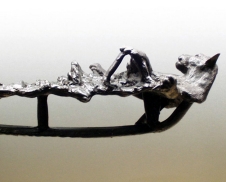

Above are photos of some furnaces and casting bays at the Imagemaker Art Foundry, along with a finished bronze sculpture. The following mini-tour should give you a better understanding of the long and tedious process of bronze casting.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Originally the sculpture started as a wire frame on to which plastiline clay was formed and detailed. This photo shows the clay with parting plates of aluminum installed for parting lines in a silicone mold.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This is a silicone mold, showing the interior which will duplicate the original clay sculpture. The elasticity of the silicone allows for multiple wax reproduction, thus allowing for editions of more than one bronze.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here we show wax being poured into a silicone mold. From this point on, each bronze takes on it's own personalities. The artist decides how much variation that he wants from one bronze to another. (The silicone molds shown are from a different model.)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Once the wax model has been removed from the mold, several hours of refinement begin . Many errors can occur in wax pouring, so re-detailing with heat and special tools is always needed. The quality of the wax model determines the quality of the finished bronze.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

All gates, sprues, and risers, which will control the bronze entry to the shell mold, and allow for the gas expulsion from the mold are installed during these stages. Once all this is accomplished, the waxes are ready for the shell molding.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The wax on the right shows the direction from which it will be poured.

SHELL MOLDING

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Please E-Mail us or call us at 417-781-3446 for imformation about a free on site tour, or information about collecting our Bronze

|

|

|

|

|

|